Production Capability

Manufacturing Capability

Since its inception, BIGTIME has continuously evolved from manual to automated manufacturing and from visual inspection to advanced monitoring systems. We consistently improve and introduce new production technologies and testing equipment to maintain the highest standards of manufacturing, quality, and product stability. Our primary objective is to deliver the best products to all our customers, and fulfilling their diverse needs remains our top priority.

Adhesion Process

上膠設備

Gluing Equipment

Automated dispensing not only controls the amount of adhesive but also enhances stability.

振動熔接機

Vibration Welding Equipment

Vibration welding is clean, fast, ideal for joining large parts, and produces high-quality bonds without the need for fasteners or adhesives.

Fixing Process

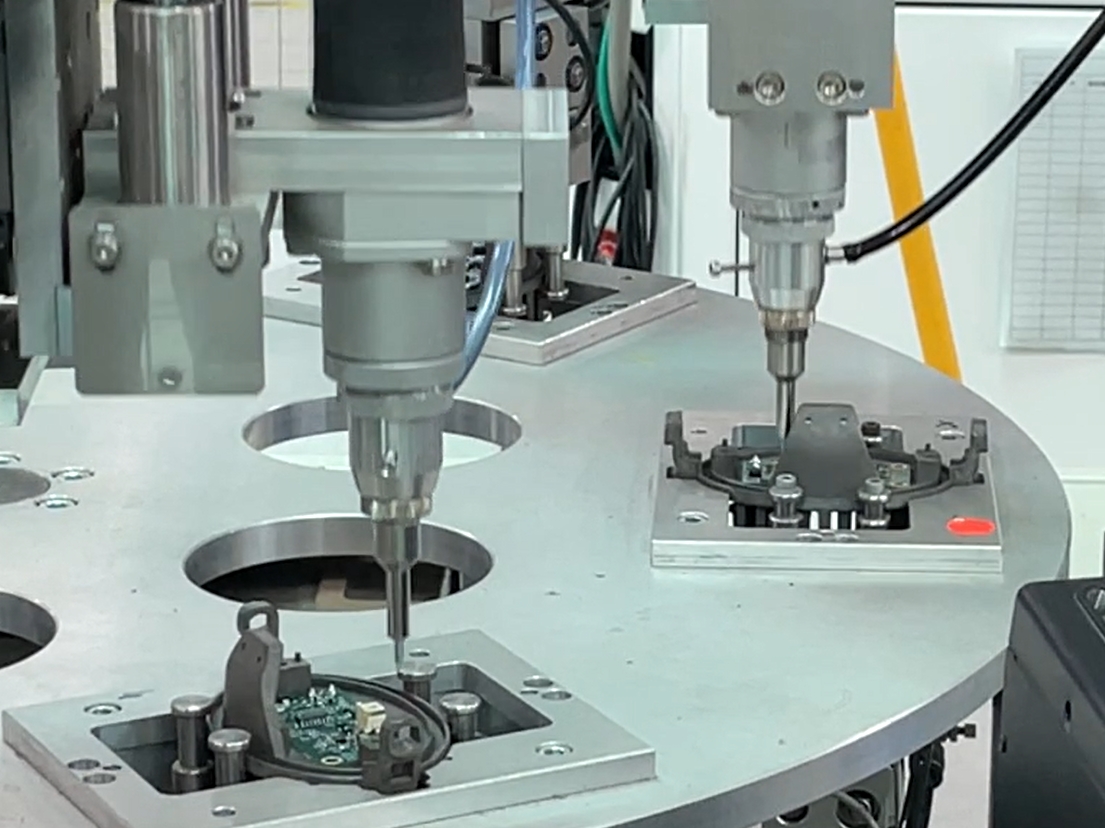

自動鎖螺絲

Automatic Screwing

The screw fastening process involves torque, rotation count, and accuracy settings and controls to ensure product stability.

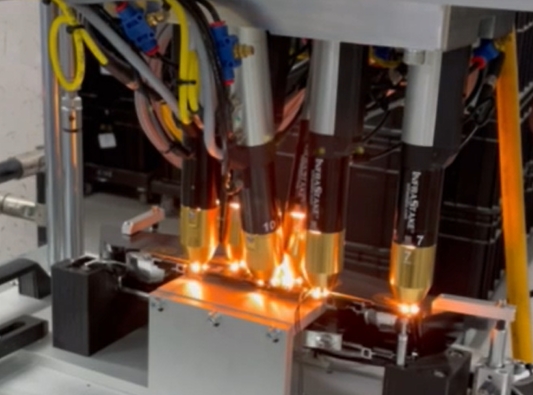

紅外鉚接

InfraStake

InfraStake is a process that utilizes focused infrared energy to heat and form a plastic boss, securely fastening objects in place.

Inspection Process

照明對準和驗證系統

Lighting alignment and validation system

The production process automatically inspects voltage, current, regulatory requirements, light patterns, and chromaticity. It also adjusts product light patterns to the same horizontal level, ensuring 100% monitoring of all products.

影像檢測

CCD

Precise measurement of SMT component position and size, ensuring 100% monitoring of all production products.

Automation - Enhancing Production Efficiency and Safety

多功能自動機械手臂

Multifunctional robot arm

Automation integrates operating procedures using versatile robotic arms, offering high flexibility, reducing staffing needs, improving efficiency, and enhancing quality.

自動化輸送物料

automation transport material

Precise measurement of SMT component position and size, ensuring 100% monitoring of all production products.