Quality Capability

Quality Assurance Capability

The company adheres to the belief of "Customer satisfaction, high quality, and on-time delivery," with the goal of meeting customer needs and providing satisfactory products and services.

Quality Organization:

Quality Control (QC):

Responsible for Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Outgoing Quality Control (OQC), in accordance with MIL-STD-1916 specifications for high-standard acceptance criteria.

Quality Engineering (QE):

Responsible for statistical analysis of process abnormalities and implementation of preventive measures, establishment of product standard operating procedures, response to customer needs and integration, handling customer complaints, and implementation of quality plans.

Quality Assurance (QA):

Responsible for document control, internal and external audits, and promotion of international quality systems.

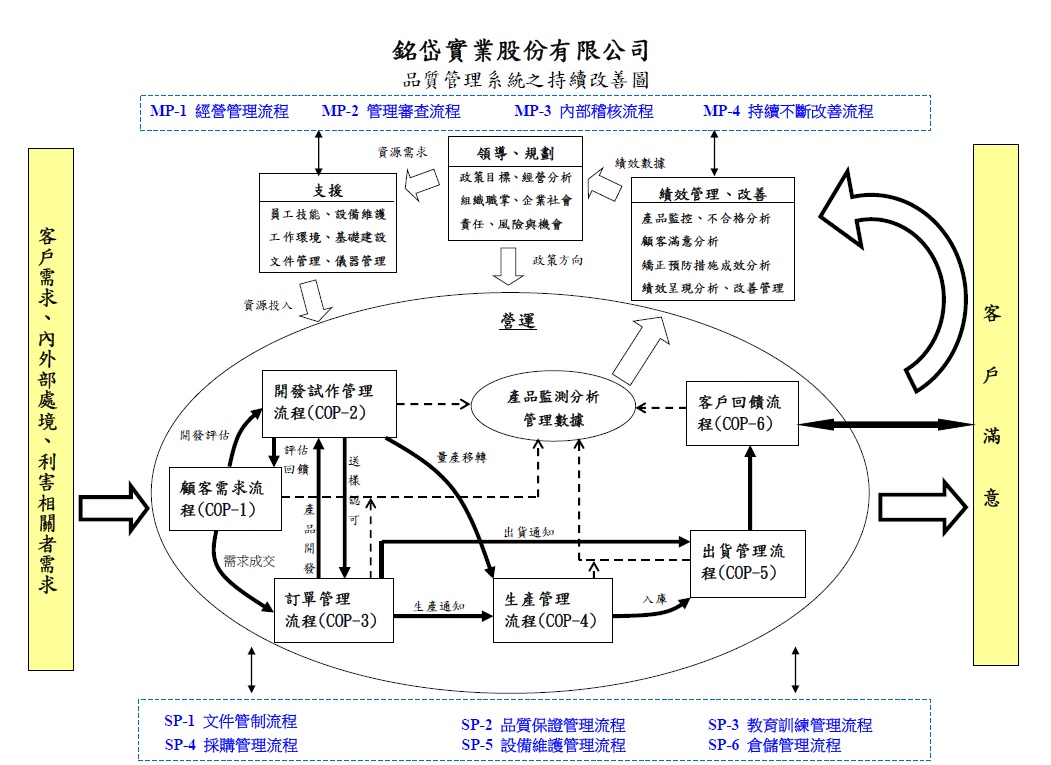

Quality System

Quality Assurance: "Customer satisfaction, high quality, and on-time delivery," and continuous improvement are the core of BigTime Auto Parts Mfg. Co., Ltd.'s quality assurance system operation.

IQC

Incoming Quality Control (IQC) is the frontline and primary control for material quality control. IQC inspectors will control the quality of incoming materials according to incoming inspection standards and equipment usage.

IPQC

In-Process Quality Control (IPQC) focuses on quality control in the production process. IPQC inspectors will inspect according to inspection points and inspection sheets in the control plan to ensure quality in the process.

OQC

Outgoing Quality Control (OQC) inspectors will conduct sampling and optical inspections before shipment, as well as relevant performance tests and appearance inspections before packaging, to ensure that the quality of shipped products meets customer standards and requirements.

Measurement Equipment

2.5D Manual Video Measuring Machine (VMM)

The manual vision measuring machine is a high-precision 2.5D vision measuring machine with optical zoom lens and Z-axis height measurement function, widely used in 3C, semiconductor, PCB, automotive parts, precision molds, etc. It helps quality assurance, quality control, and R&D personnel to improve product precision and accuracy.

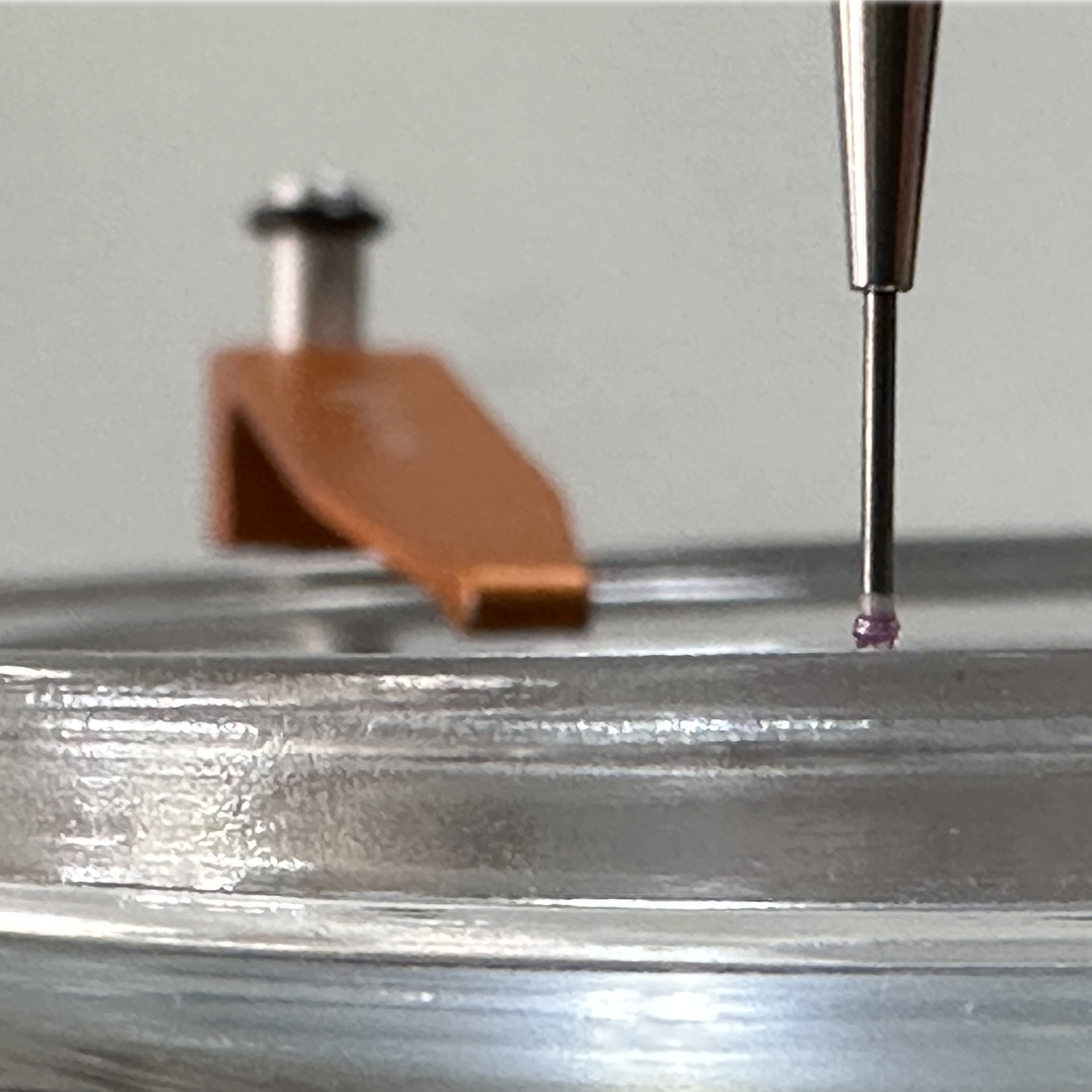

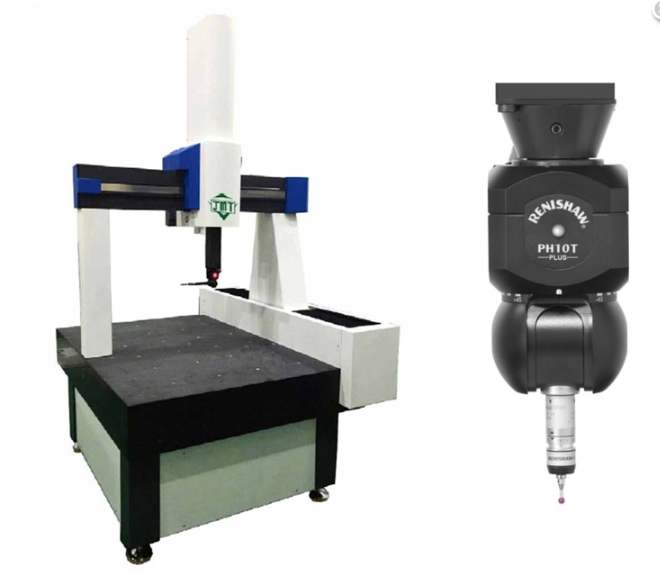

3.0D Coordinate Measuring Machine (CMM)

The high precision of the three-dimensional measuring machine (CMM) can detect and analyze small workpieces or product measurements. It helps the company detect problems in the production stage and take measures to improve product quality, reduce defect rates and customer complaints, enhance customer trust in products, and improve the company's competitiveness and market position.

Laboratory Equipment

Goniophotometer

All designed products must pass through the goniophotometer to verify compliance with all optical regulations, such as DOT, SAE, ECE, CCC, etc. Passing optical regulations testing is part of our commitment to customers and an important audit process for product quality.

Programmable Temperature and Humidity Machine

The purpose of this constant temperature and humidity machine is to simulate the adaptability and characteristics of products under climate conditions of temperature and humidity combinations. This test can meet international specifications and alleviate customer concerns about climate change.

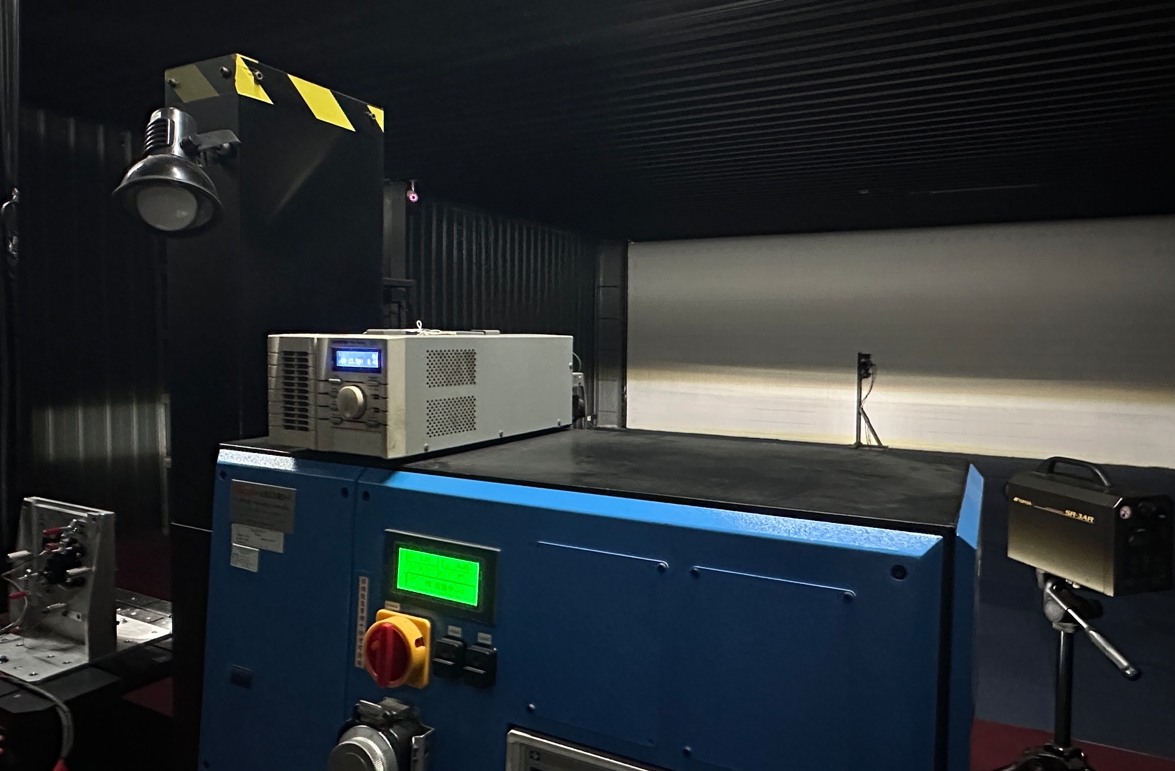

Water Spray Chamber

All designed waterproof products will undergo testing and verification using a water resistance tester. This ensures that the products do not accumulate water or leak, which could cause circuit short circuits, failures, or unsafe conditions.

Salt Spray Chamber

The surface treatment of workpieces will be processed and tested according to customer requirements to ensure long-term corrosion resistance of the products.

Standard Electromagnetic Vibrator

The electromagnetic vibration tester has wide vibration response frequency, high control precision, can simulate various waveforms and specifications. It helps the company understand the product structure and reflect on whether the device under vibration environment causes unpredictable damage.

Professional Certifications

IATF 16949:2016

ISO 9001:2015

ISO 14001:2015

E4